Swiss Quality, Precision & Reliability

Company

alupak is a leading manufacturer of deep-drawn aluminum packaging and works in long-term and trusting partnerships for and with customers.

With over 200 dedicated employees and using the latest technology, we manufacture high-quality products.

Strong growth supported by high investment volumes distinguishes alupak as a medium-sized company.

Philosophy & Mission

What moves us

alupak has always been driven by the desire for special packaging solutions. In close partnership with customers, suppliers and partners, this often results in end products that were not even conceivable at the outset. Or did you know that it originally seemed impossible to produce capsule packaging for premium coffee specialties in today’s dimensions?

With modern machinery and a motivated and dedicated team, we are in a position to set trends in aluminum packaging.

With comprehensive, decades-long know-how and creativity, we are happy to take on new challenges and develop tailor-made solutions independent of industry-typical conventions.

Ethics & CoC

Code of Conduct

We work on the further development of the materials used, alternative manufacturing and finishing processes to achieve optimal solutions for your products and applications.

We improve our own manufacturing processes by constantly increasing productivity through technical innovations. Process improvement is embedded in our culture.

We find solutions in interdisciplinary teams as well as with competent, external partners.

Management

Leadership Team

Andreas Zenz

CEO

Christoph Geiser

CFO

Gökhan Kenar

COO

Philippe Bay

CTO

Shareholder

Advisory Board

Dr. Tosja Zywietz, Peter Brogle, Angela Kolb, Patricia Bumann-Kolb (Board President), Bengt Steinbrecher, Felix N. Steinbrecher (left to right)

Who we are, what we stand for

alupak - At a glance

Foundation

You can find our origin already in 1962.

Capacity

With a production capacity of over 10 billion packages per year, we have a wide range of possibilities.

Team

Over 200 employees contribute to our joint success.

Facts

Over 150 million CHF (2022)

High level of investment

Stable financing

0-failure philosophy

Our efficient production processes aim for a 0-defect rate.

Shareholder

The KOLB Group is our majority shareholder:

1.200 employees

300 Mio. € (2022)

Our strengths

- Specialist in deep-drawn aluminum packaging

- Development of complex tools, products and processes

- Highly automated production processes for high-volume orders

- Distinct expertise in certified products and production processes

- High quality standard / 0-defect philosophy

- International Focus

- Stable financing base and pronounced investment strength

Creating new things together & setting standards

Innovation

We work on the further development of the materials used, alternative manufacturing and finishing processes to achieve optimal solutions for your products and applications.

We improve our own manufacturing processes by constantly increasing productivity through technical innovations. Process improvement is embedded in our culture.

We find solutions in interdisciplinary teams as well as with competent, external partners.

Quality

Quality first - our quality management system

0 Failure

We are committed to the 0 defects target.

ISO Certification

ISO 9001 certification is the basis for our daily activities.

Ethical business practice

We are committed to ethical business practices and are certified according to SMETA / Sedex.

Vision System

Specially designed camera systems enable 100% inline inspection of essential criteria.

Test and measurement laboratory

Our own test and measurement laboratory is equipped with the most modern test and measurement devices.

At alupak we maintain a hygiene concept for the production and supply of packaging to the food industry.

Compliance with food regulations and continuous risk assessment according to HACCP, as well as complete traceability through the logistics chain, provide safety and protection. Our products are kosher and Hall.

Advance quality planning is our principle for safe and stable product quality and robust production processes.

Regular customer audits, internal audits, and supplier audits ensure stable processes and quality.

Continuous training of all employees is part of our knowledge management.

Environment

Ecology / Sustainability

alupak is committed to the preservation of nature and a world worth living in. That is why alupak recycles 100% of all raw materials and production scrap and uses the waste heat from production. Through initiatives, as an electricity-intensive company, we are constantly examining ways to save energy, for example through automatic light switching, LED lamps or optimization of compressed air consumption, and we agree on energy targets with nationwide initiatives.

We also support aluminum for ecological reasons as a modern packaging material because of its very special properties for protecting products: Aluminum is easy to shape, stable, impermeable to light and gas, heat-resistant, hygienic and tasteless. Aluminum is resource-saving when it helps to save weight and protect valuable goods from damage and spoilage. Thus, packaging made of aluminum helps to effectively protect food, pharmaceuticals and other sensitive goods produced with much higher energy and water consumption. This depends on the specific conditions of use and is confirmed by independent environmental life cycle analyses.

Aluminum can be recycled an infinite number of times with no loss of quality and a 95% reduction in energy use compared to the production of primary aluminum. A variety of different activities by packaging manufacturers, associations, NGOs and national initiatives show a good response and increasing recycling rates.

Project

Heat Recovery

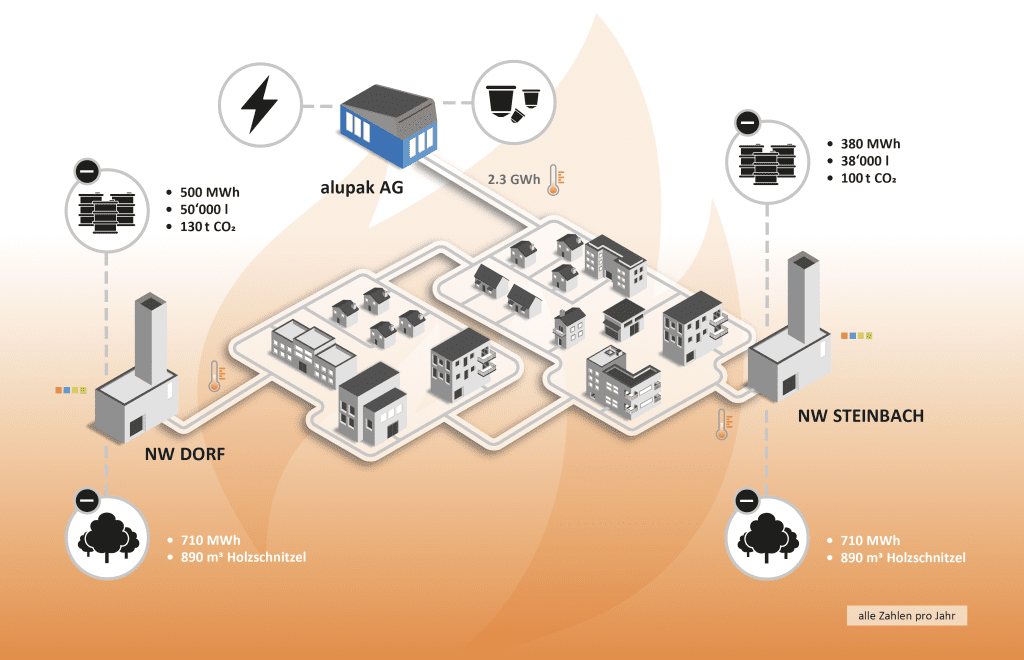

Energie Belp AG, together with alupak AG, is exploring new, innovative ways to promote sustainability.

A heat recovery project will be implemented by 2024, which, in addition to remarkable savings in the local heating supply for Belp, will also lead to a reduction in CO2 emissions of around 230 tons per year.

Creating the safest workplace together

Safety

Safety is our priority, both in the workplace and in our personal lives. It is important to us to offer safe and ergonomically optimized workplaces, to allow our employees to go home healthy at the end of the working day. We support the SUVA charter and develop a safety culture.

- Health

There is nothing more valuable than human health,

that is why it is our top priority.

- Safety

Whether through patrols or proactive safety measures –

daily attention is paid to safety to prevent accidents.

- Every accident is one too many

It should not happen that an accident happens again. That’s why we analyze all accidents, even near-accidents, in detail and take action.

SIBE's (safety officer)

Specially trained and responsible, they pay special attention to safe workplaces and sensitize employees on a daily basis to avoid risks and take care of each other.