Energie Belp AG, together with alupak AG, is exploring new, innovative ways to promote sustainability.

A heat recovery project will be implemented by 2024, which, in addition to remarkable savings in the local heating supply for Belp, will also lead to a reduction in CO2 emissions of around 230 tons per year.

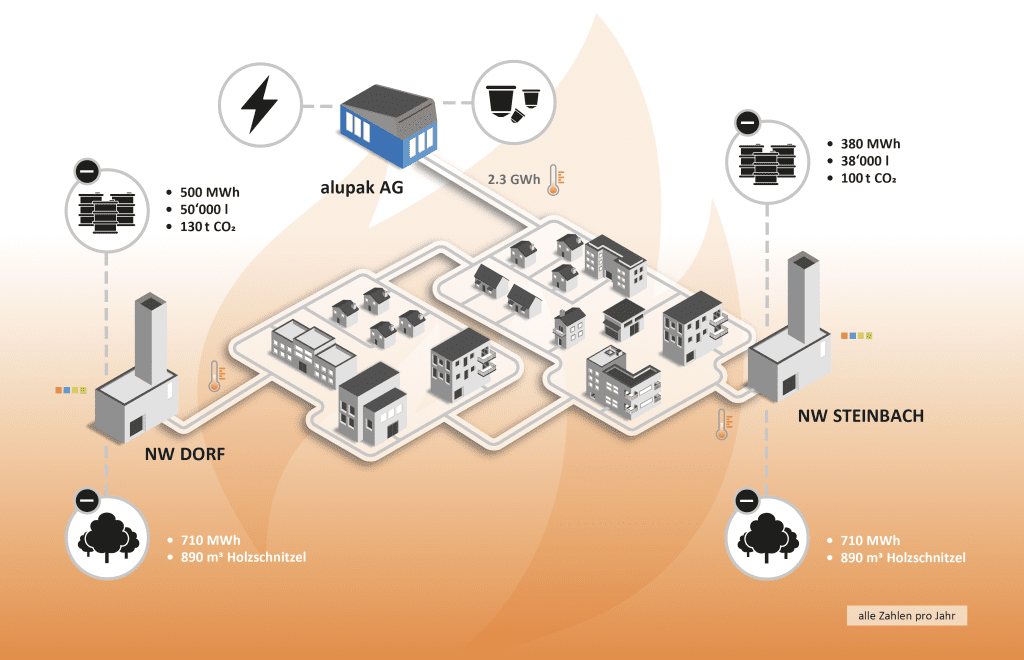

The project connects the alupak production building with the Steinbach heating center operated by Energie Belp. The recovered process heat of 2.3 gigawatt hours per year is fed into the local heating network. This corresponds to the energy consumption of around 100 single-family homes.

The cooperation between the two companies will have a significant impact on the CO2 emissions of the local heating supply: after a later planned connection of the two heating supplies Dorf and Steinbach, it will make it possible to substitute the entire consumption of heating oil, which corresponds to a saving of around 90,000 liters of fossil fuel per year and thus saves around 230 tons of CO2 emissions. In addition, almost 1,800 cubic meters of wood chips are saved each year. For alupak, the project is one of numerous measures to reduce its CO2 footprint. It also underlines the commitment of both companies to environmental protection and sustainability.

Representatives of Energie Belp and alupak at the ground-breaking ceremony